Spheroidal Graphite Cast Iron Roll

- SDMT

- HEBEI

- within 75 days after advanced payment

- 800 tons/month

● wide adaptability

● high rolling accident resistance

● high wear resistance

● lower roll consumption

● according to the customer's rolling condition,personalized roll material design is carried out to reduce the user's roll consumption

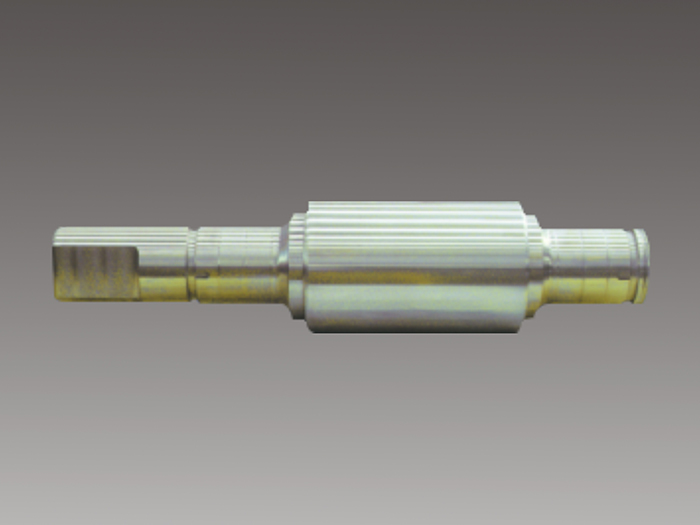

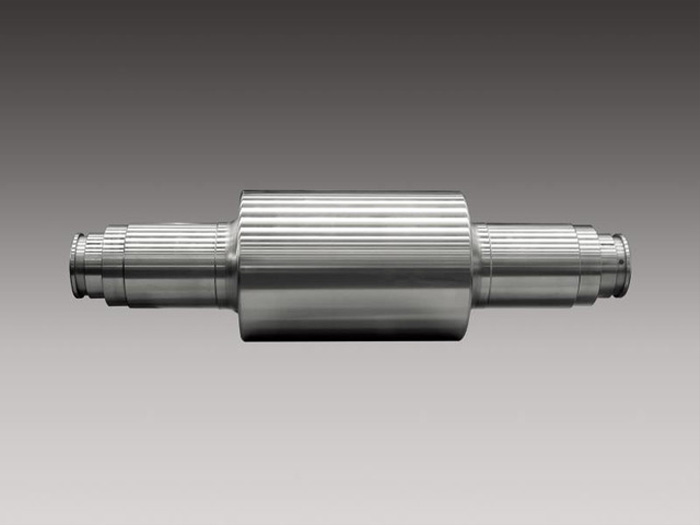

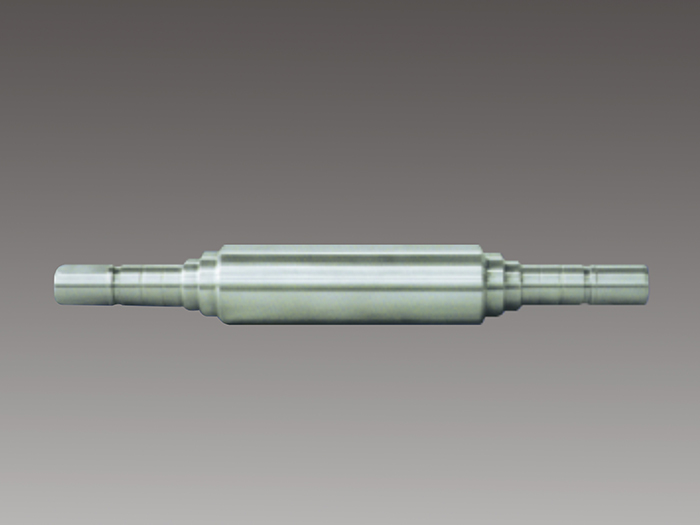

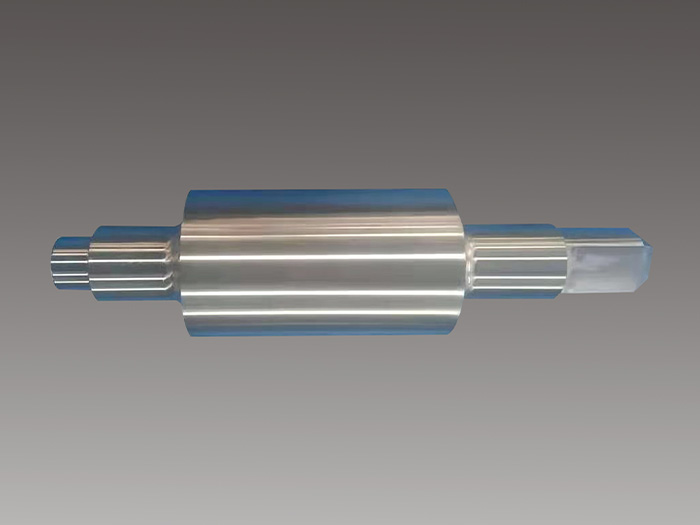

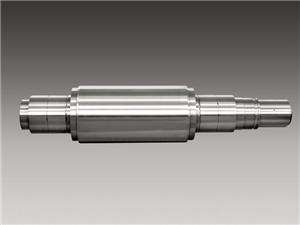

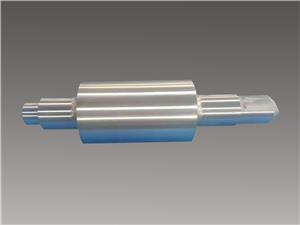

Nodular cast iron rolls

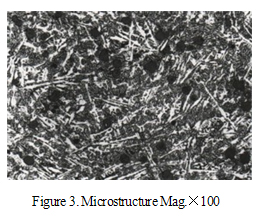

Thanks to its higher content of Ni and Mo alloys, pearlite, bainite and martensite matrixes with excellent performance are produced. The graphite is in spherical form, good heat transfer property and high tensile strength. Through changing the structure into bainite and martensite matrix, chemical composition of needly-like spherical iron of heat treatment, a dense reticular primary cementite with high wear-resistance is produced.

Mechanical properties

Mechanical properties | Data(centrifugal) | Data(static) |

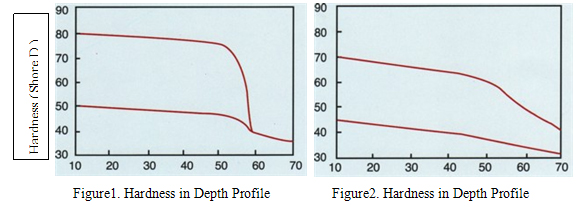

Roll surface hardness | HSD50-80 | HSD45-70 |

Roll neck hardness | HSD35-55 | HSD35-55 |

Tensile strength of core | ≥400Mpa | ≥300Mpa |

Material chemical composition

Material | C | Si | Mn | Ni | Cr | Mo | Mg | Hardness |

SGP I | 2.9-3.5 | 1.4-2.2 | 0.3-1.0 | 0.5-1.5 | 0.2-0.6 | 0.2-0.6 | ≥0.04 | 50-65 |

SGP II | 2.9-3.5 | 1.4-2.2 | 0.3-1.0 | 1.0-3.0 | 0.2-1.2 | 0.2-0.6 | ≥0.04 | 50-70 |

SGA | 3.0-3.5 | 1.4-2.0 | 0.3-1.0 | 3.0-4.5 | 0.2-1.2 | 0.6-1.0 | ≥0.04 | 65-80 |

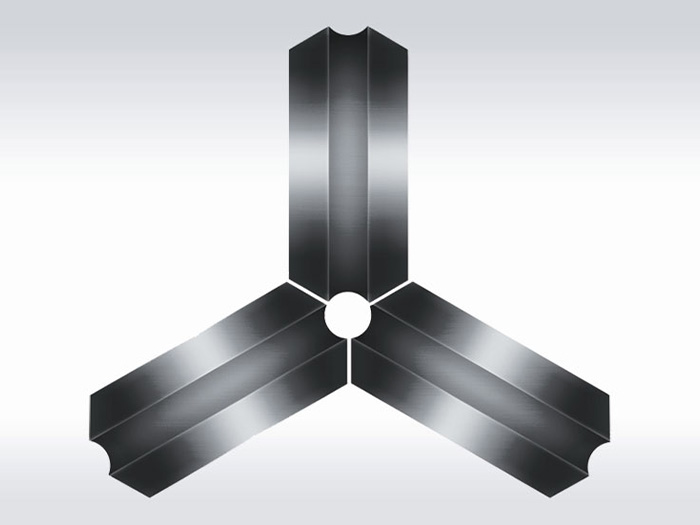

Application:Nodular cast iron roll is used in finishing two-roll and support roll in various tandem mills such as rough rolling mills,intermediate rolling mills,bar finish rolling mills,section mills,strip steel mills,also hot-rolled strip steel mills for production of stainless steel.

Rolls pacakge