Infinite Chilled Cast Iron Roll rebar mill rolls

- SDMT

- HEBEI

- within 75 days after advanced payment

- 800 tons/month

● wide adaptability

● high rolling accident resistance

● high wear resistance

● lower roll consumption

● according to the customer's rolling condition,personalized roll material design is carried out to reduce the user's roll consumption

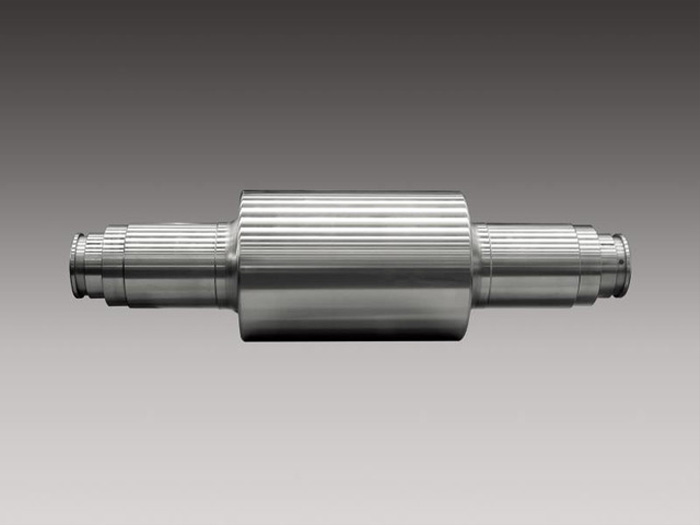

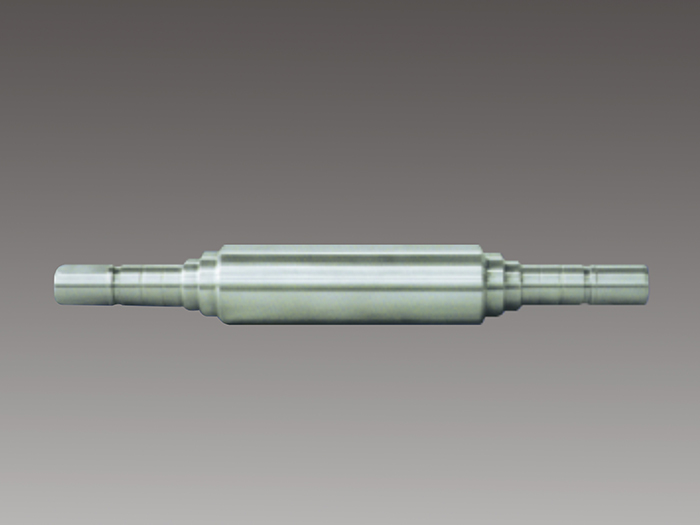

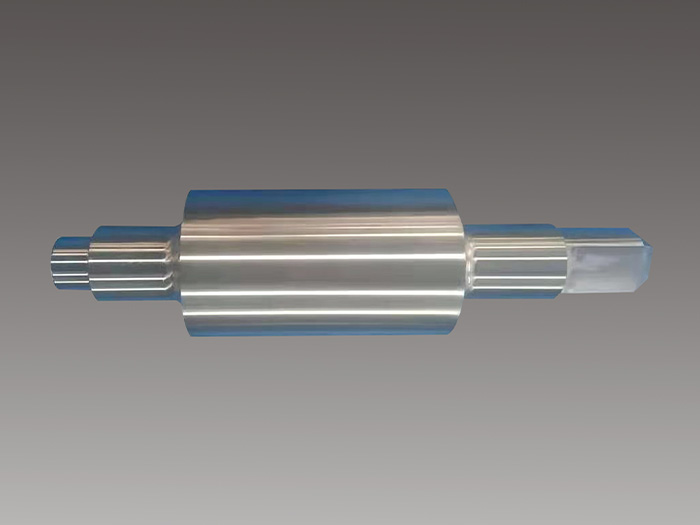

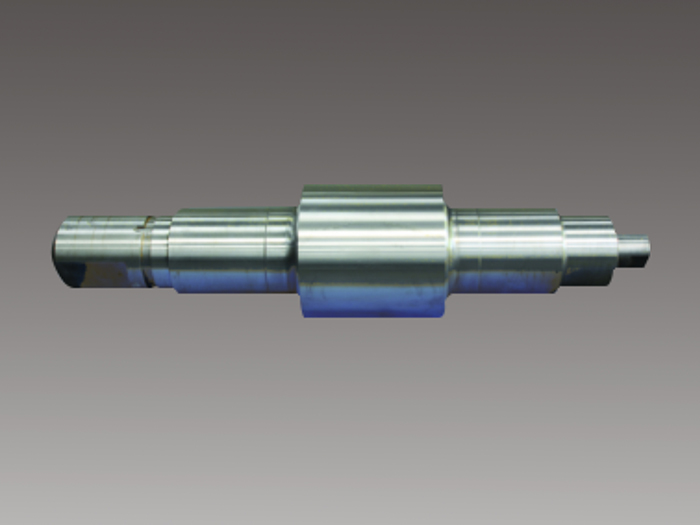

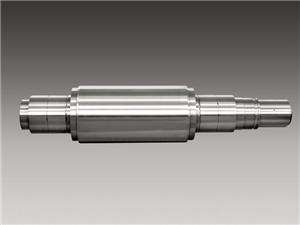

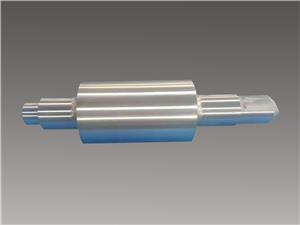

Infinite chilled cast iron roll

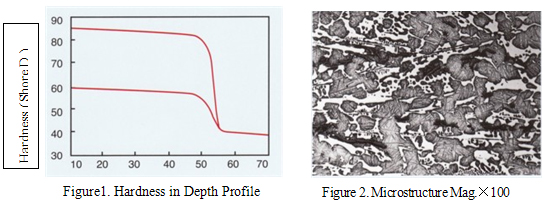

Centrifugal composite infinite chilled cast iron roll:the outer layer has rather high metallurgical character;almost without changing for graphite quantity in depth location that from the surface to the heart that almost the same hardness;the iron rolls hardness is mainly determined by the basis structure,as austenite,bainite or martensite.

Iron roll mechanical properties

Mechanical properties | Data |

Roll surface hardness | HSD60-85 |

Roll neck hardness | HSD35-48 |

Tensile strength of core | ≥400Mpa |

Iron roll chemical composition

Material | Chemical composition | Hardness | |||||

C | Si | Mn | Ni | Cr | Mo | ||

Chilled I | 3.1-3.5 | 0.35-1.0 | 0.4-1.0 | 0.5-1.0 | 0.5-1.0 | 0.2-0.6 | 60-75 |

Chilled II | 3.1-3.5 | 0.35-1.0 | 0.4-1.0 | 1.0-2.0 | 0.7-1.2 | 0.2-0.6 | 62-72 |

Chilled III | 3.1-3.5 | 0.35-0.9 | 0.4-1.0 | 2.0-3.0 | 0.8-1.6 | 0.2-0.6 | 65-75 |

Chilled IV | 3.1-3.5 | 0.35-0.9 | 0.4-1.0 | 3.0-5.0 | 1.0-1.6 | 0.2-0.6 | 75-85 |

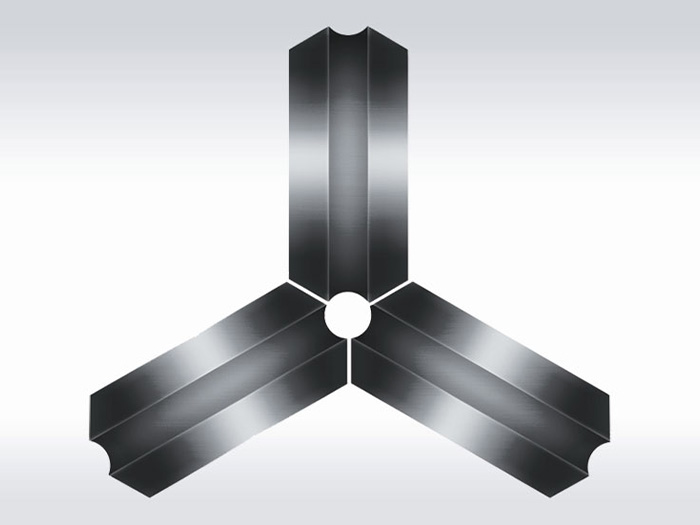

Application

Infinite cast iron roll is used in hot steel strip finishing rolling mill stand,continuous re-bar finishing rolling mill stand,high speed wire pre-finishing rolling mill stand,small section intermediate rolling mill and finishing rolling front mill,as well as thin steel strip mill and straightening mill stand.

Rolls package