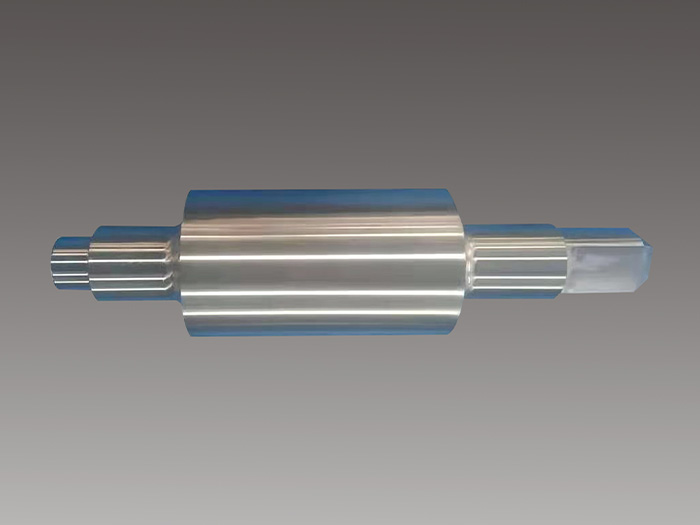

Graphitic Steel Roll

- SDMT

- HEBEI

- within 75 days after advanced payment

- 800 tons/month

● wide adaptability

● high rolling accident resistance

● high wear resistance

● lower roll consumption

● according to the customer's rolling condition,personalized roll material design is carried out to reduce the user's roll consumption

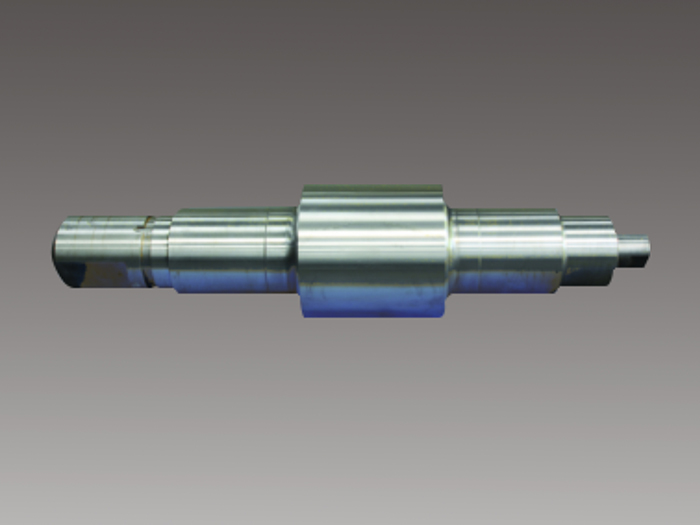

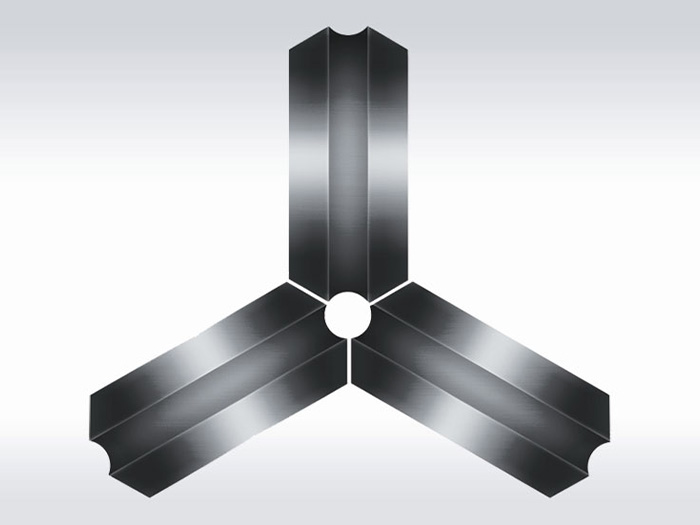

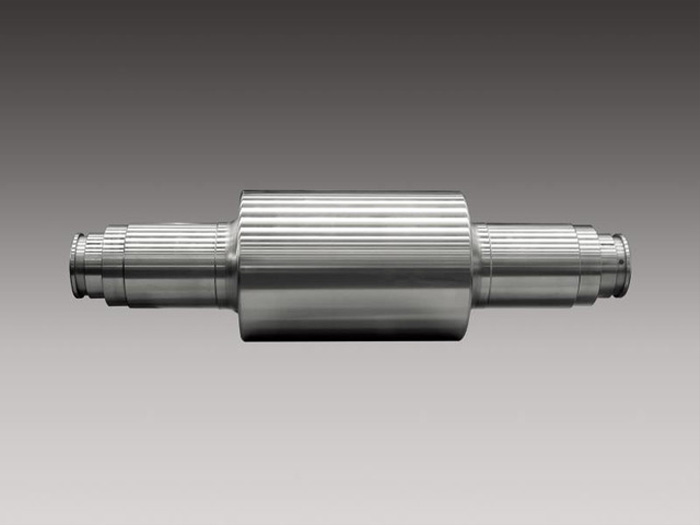

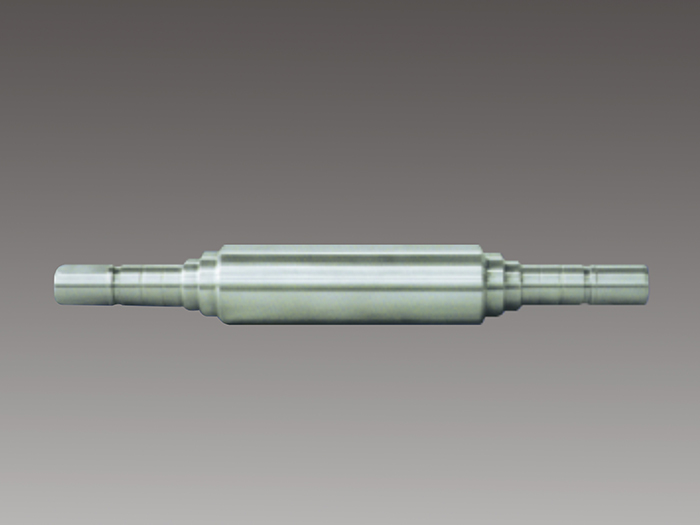

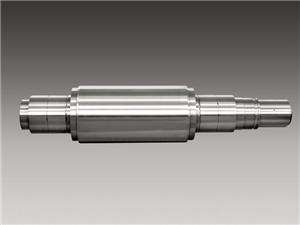

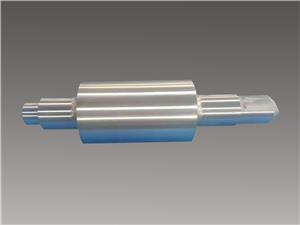

Centrifugal composite semi-steel and graphite steel roll and roll ring

Specification: centrifugal composite steel and graphite steel

Applications: it is mainly used in section mills, finish rolling front frames of hot-rolled strip as well as rough rolling and intermediate rolling frames for rod and wire

Product character:For graphite steel roll,its microstructure consists matrix and carbide and its carbide rate is between 1.3% to 2.6%.With different alloy element and heat treatment method,the matrix is pearlite and bainite.As we know that the Cr element can stable the carbide,V element can improve the high temperature property,Ni can strengthening matrix.Semi-steel has the character of small hardness drop,good wear resistance,good high temperature resistance and over-loading character.

Material mechanical properties

Mechanical properties | Data |

Roller surface hardness | HSD 48~70 |

Roll neck hardness | HSD 35~50 |

Core tensile strength | ≥400MPa |

Material chemical composition

C | Si | Mn | Ni | Cr | Mo |

1.1~2.4 | 0.34~0.8 | 0.6~1.4 | ≥0.3 | 0.8~1.5 | 0.2~0.8 |