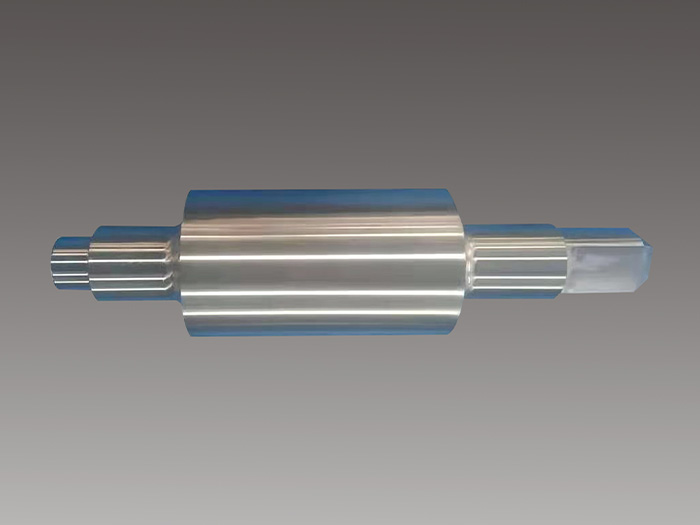

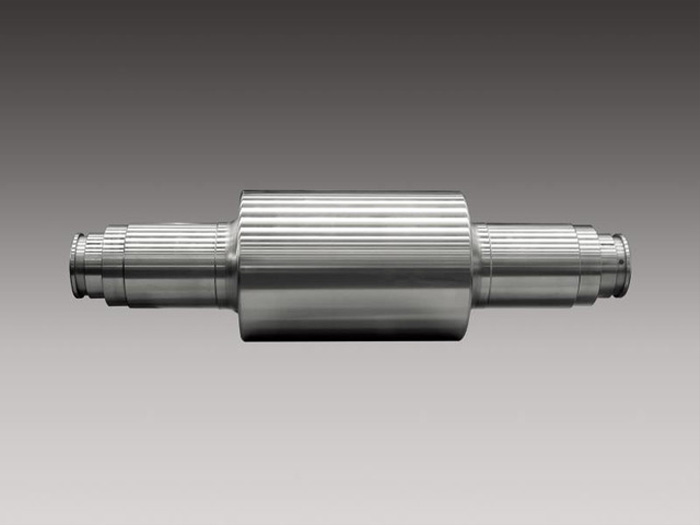

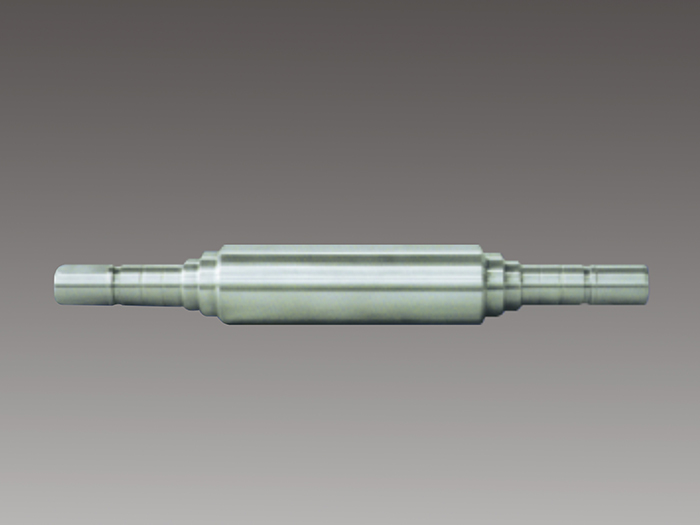

Chilled Cast Iron Roll

- SDMT

- HEBEI

- within 75 days after advanced payment

- 800 tons/month

● wide adaptability

● high rolling accident resistance

● high wear resistance

● lower roll consumption

● according to the customer's rolling condition,personalized roll material design is carried out to reduce the user's roll consumption

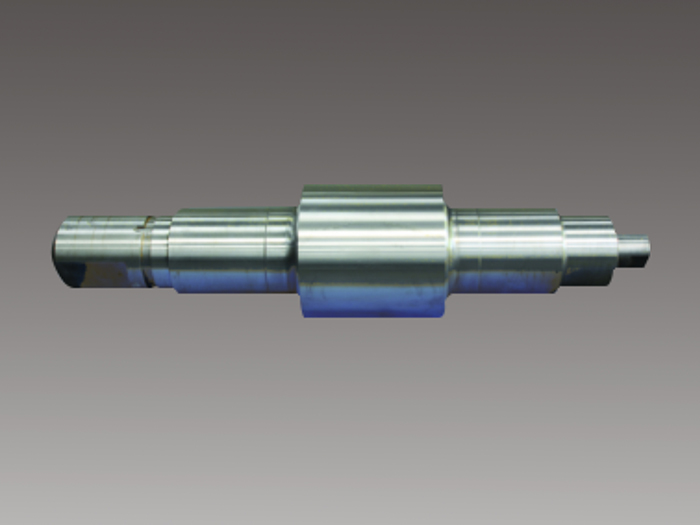

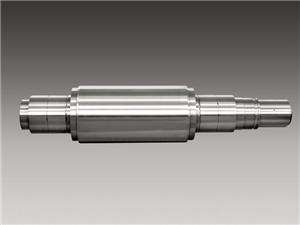

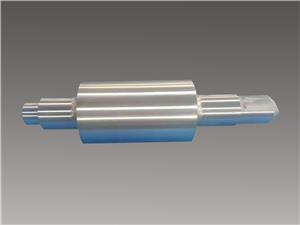

Chilled cast iron roll

Properities

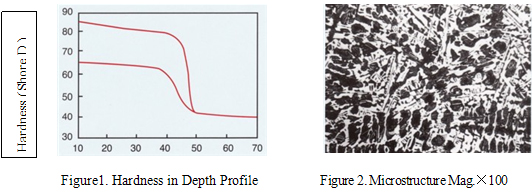

Centrifugal composite chilled cast iron roll:as rolls surface is covered by chilled structure,the excellent wear resistance of the roll is guaranteed;the iron roll hardness and basic inner structure will be determinded by the site usage condition.

With centrifugal way,the whole roll working layer can be without graphite.With core using spheroidal graphite cast iron,the resistance is improved both on wear resisitance and fracture resisitance.

Mechanical properties

Mechanical properties | Data |

Roll surface hardness | HSD65-85 |

Roll neck hardness | HSD35-48 |

Tensile strength of core | ≥400Mpa |

Chemical composition

Material | Chemical composition | Hardness | |||||

C | Si | Mn | Ni | Cr | Mo | ||

Chilled I | 3.1-3.5 | 0.35-0.50 | 0.3-0.8 | 0.8-2.0 | 0.3-0.8 | 0.2-0.6 | 60-75 |

Chilled II | 3.1-3.5 | 0.35-0.50 | 0.3-0.8 | 2.0-3.0 | 0.5-1.2 | 0.2-0.6 | 65-80 |

Chilled III | 3.1-3.5 | 0.35-0.50 | 0.3-0.8 | 3.0-4.5 | 0.6-1.5 | 0.2-0.6 | 70-80 |

Application

The chilled cast iron roll is used in wire mills,small section and re-bar finished product as well as for light material.

Iron roll package