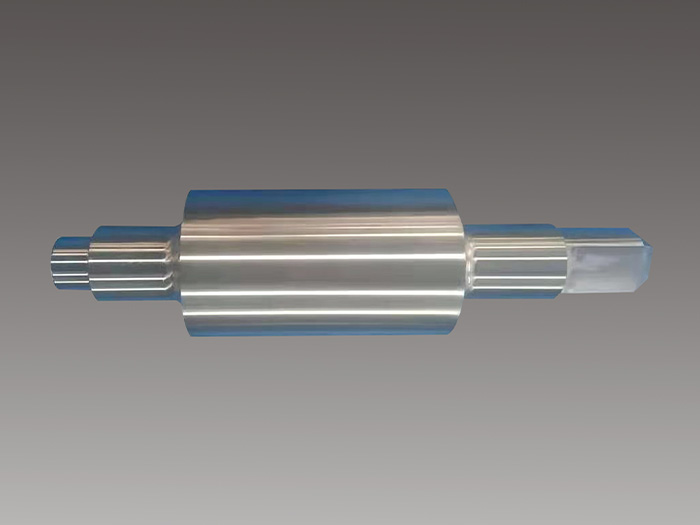

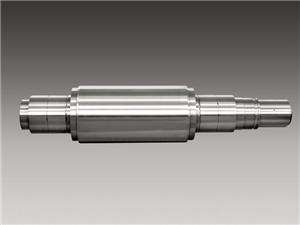

High Chromium Cast Iron Roll

- SDMT

- HEBEI

- within 75 days after advanced payment

- 800 tons/month

● wide adaptability

● high rolling accident resistance

● high wear resistance

● lower roll consumption

● according to the customer's rolling condition,personalized roll material design is carried out to reduce the user's roll consumption

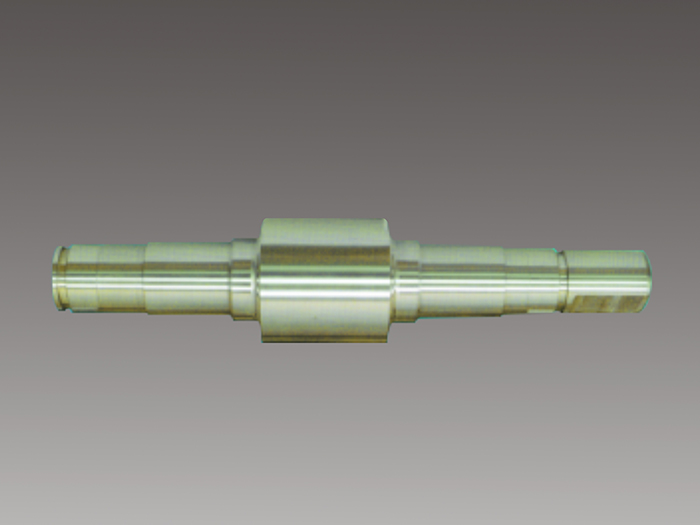

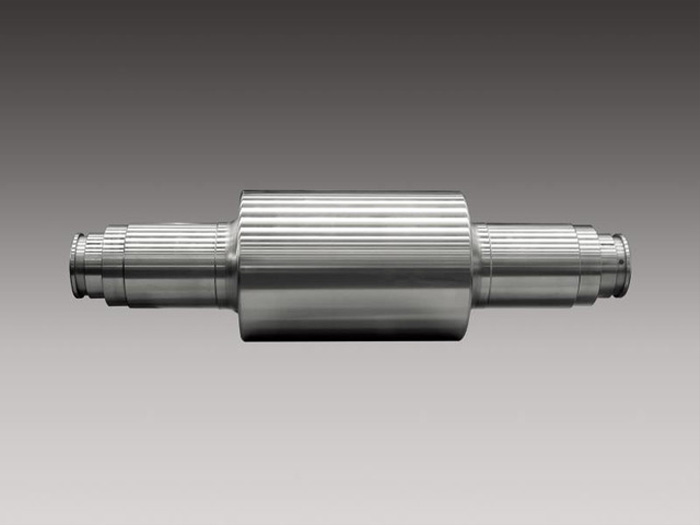

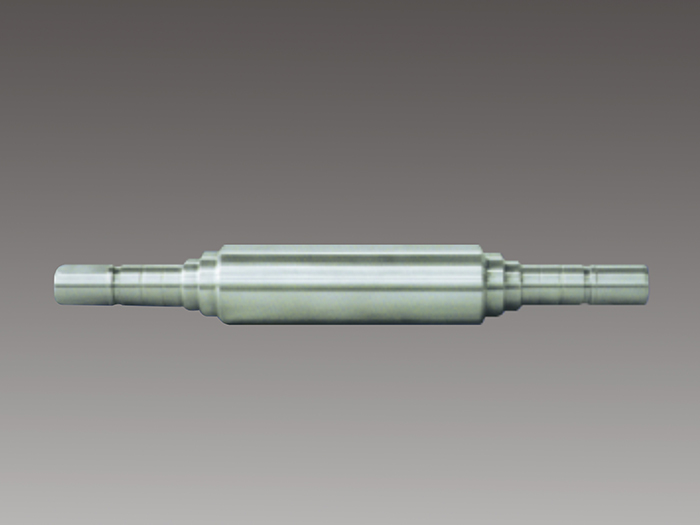

High chromium cast iron roll

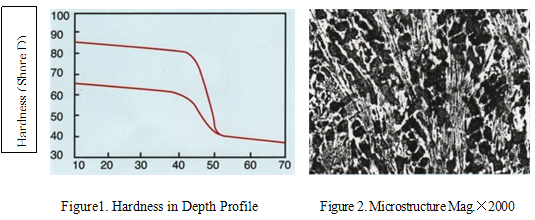

Thanks to its high content of M7C3, type carbide in range of 20-30% and discontinuous network distribution of carbide, the roll offers a high wear resistance performance. The matrix is finely-disseminated secondary carbides (M7C3、M23C5 and M3C types), increasing therefore the wear resistance of roll, The Cr2O3 enriched oxide film on the roll surfaces is highly resistant to oxidization and plastic strain, making the roll extremely suitable for steel hot milling process.

Mechanical properties

Mechanical properties | Data |

Iron roll surface hardness | HSD65-85 |

Iron roll neck hardness | HSD35-48 |

Tensile strength of core | ≥450Mpa |

High chromium cast iron roll chemical composition

Material | C | Si | Mn | Cr | Ni | Mo |

High chromium cast iron roll | 2.4-3.0 | 0.4-0.6 | 0.8-1.2 | 16-20 | 0.8-1.5 | 0.8-2.0 |

Application:high chromium cast iron roll is mainly used for the front 3 and 4 finishing racks of continuous strip mill and the post rack rough mill.

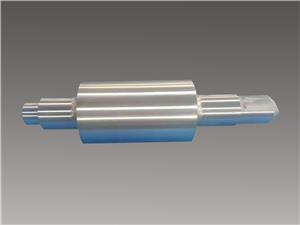

High chromium roll package