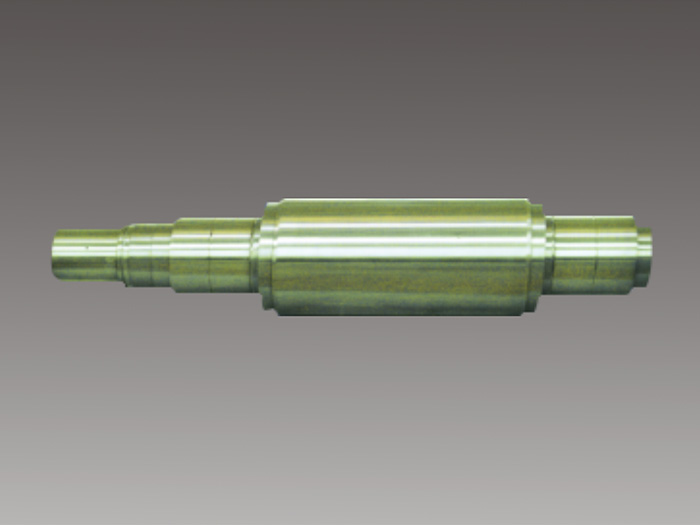

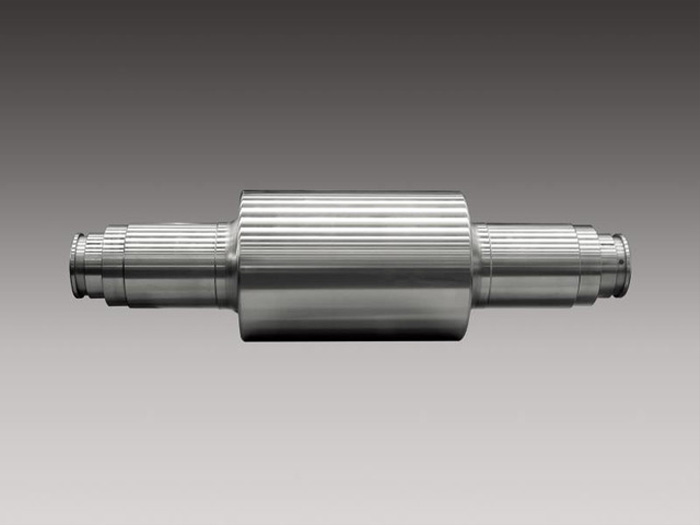

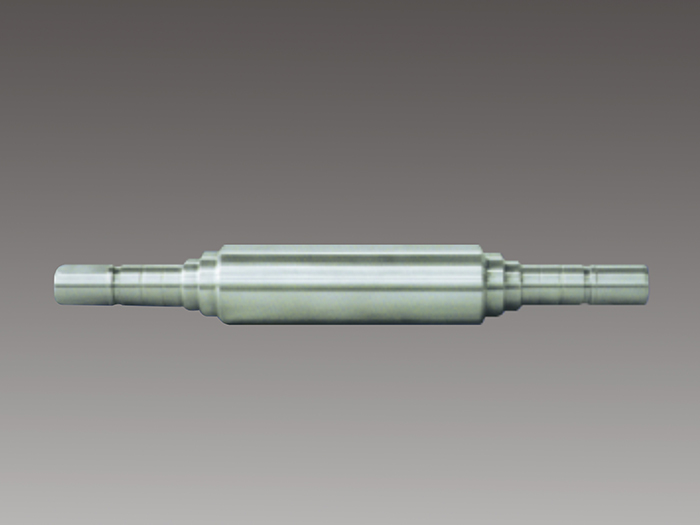

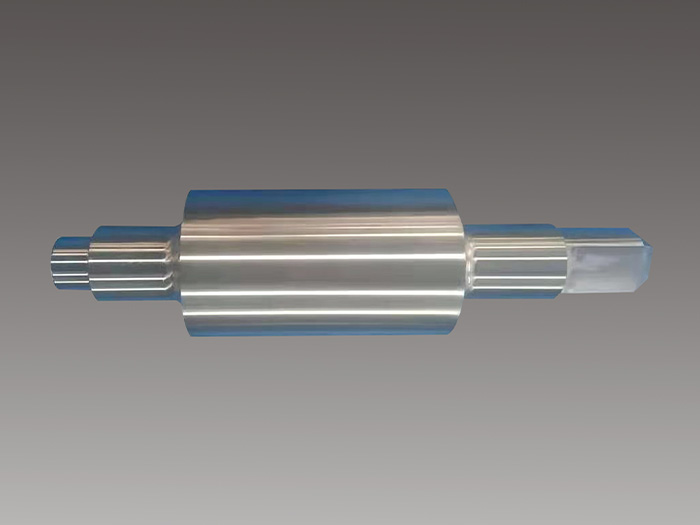

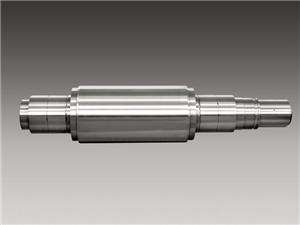

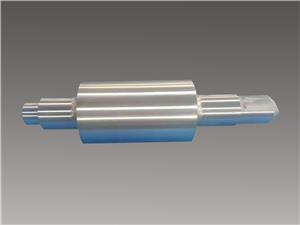

Alloyed Steel Roll

- SDMT

- HEBEI

- within 75 days after advanced payment

- 800 tons/month

● wide adaptability

● high rolling accident resistance

● high wear resistance

● lower roll consumption

● according to the customer's rolling condition,personalized roll material design is carried out to reduce the user's roll consumption

Alloyed steel roll

Diffeent alloyed steel material

Material | Chemical composition(%) | Application | ||||||||||

C | Si | Mn | Cr | Ni | Mo | V | Nb | P | S | |||

Alloy steel | AS651 | 0.6-0.7 | 0.2-0.6 | 0.5-0.8 | 0.8-1.2 | 0.2-0.5 | 0.2-0.45 | - | - |

≤ 0.035 |

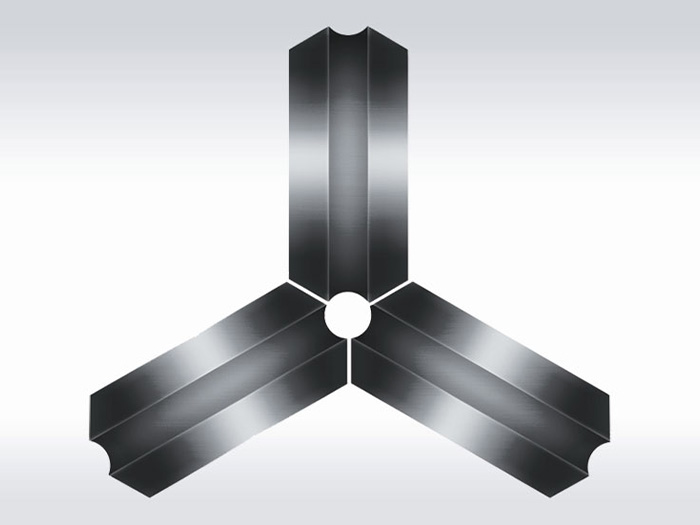

≤0.03 | Section mill,wire and re-bar roughing rolls;strip steel back up roll,vertical roll;section steel universal mill |

AS70 | 0.65-0.75 | 0.2-0.45 | 0.9-1.2 | - | - | - | - | - | ||||

AS701 | 0.65-0.75 | 0.2-0.45 | 1.4-1.8 | - | - | - | - | - | ||||

AS7011 | 0.65-0.75 | 0.2-0.45 | 1.4-1.8 | - | - | 0.2-0.45 | - | - | ||||

AS75 | 0.70-0.80 | 0.20-0.45 | 0.6-0.9 | 0.75-1.0 | - | 0.2-0.45 | - | - | Billet roughing stand;section mill universal stand;hot mill strip steel roughing stand | |||

AS751 | 0.70-0.80 | 0.2-0.7 | 0.7-1.1 | 0.8-1.5 | ≥0.2 | 0.2-0.6 | - | - | ||||

Cr3 | 0.20-0.50 | 0.2-0.7 | 0.5-1.3 | 2.4-3.5 | ≤0.8 | 0.3-0.6 | 0.05-0.20 | - | ≤0.08 | ≤0.05 | hot mill strip steel support roll,roughing roll;cold steel finishing and back up roll | |

Cr5 | 0.30-0.55 | 0.2-0.7 | 0.3-1.1 | 4.7-5.4 | ≤0.5 | 0.5-0.85 | 0.50-0.85 | - | ||||

Material mechanical properties

Material | Mechanical properties(HSD) | |

Roller surface hardness | Roll neck hardness | |

Alloy AS651 | 35-45 | ≤45 |

Alloy AS70 | 32-42 | ≤42 |

Alloy AS701 | 35-45 | ≤45 |

Alloy AS7011 | 35-45 | ≤45 |

Alloy AS75 | 35-45 or 40-50 | ≤45 |

Alloy AS751 | 35-45 or 40-50 | ≤45 |

Alloy Cr3 | 58-63 | 30-40 |

Alloy Cr5 | 68-73 | 30-40 |

Package