How to improve the rolls using life

How to improve the rolls using life

Date:June 20th 2021

Place:Meeting room

Staff:sales department&production department

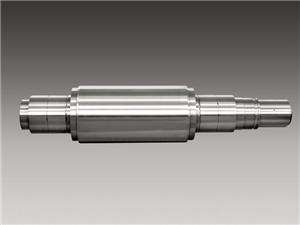

Rolls is the most important part during the production for different steel products,such as steel strip,different section,rebar,wire and the other products which is related to steel.Meanwhile rolls is the most important consumable part for the mill .

To improve the rolls using life is one of the most valuable topic for us to help the customers to save the cost.To reach this aim,we have made the special meeting for talking on this topic.

The below the some of the way that we have conclued on it :

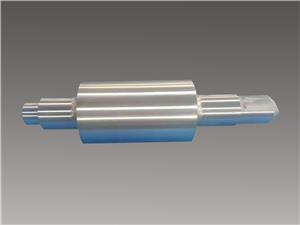

1. Preheat.Before the running of the rolls,we make the preheat.In this case,we can shorten the temperature gradient on rolls surface and inner to reduce the stress.

2. Cooling of rolls:As the rolls with high alloy content for hot strip mill finishing work mill stand,the thermal conductivity of the rolls is not good that the water cooling is important for the rolls.General speaking,the temperature on rolls surface for roughing rolls should be with 70℃ meanwhile finishing rolls with 60℃.The rolling mill both for domestic and international,the average water consume for every cm rolls length has added from 3m³/cm.h to 5m³/cm.h.The adding for cooling water is not only reducing the crack of the rolls but also offering the better usage condition for choosing the more wear resistance material.

3. Grinding of rolls:Grinding is the most efficient way for eliminating the roll crack,preventing the rolls broken and spalling.After the roll has off the mill,the inspection report record is necessary.The grinding area should be added to eliminate all the crack.To eliminate the crack absolutely,NDT should be cooperated in,as magnetic particle inspection and ultrasonic inspection.