PQF rolling mill in seamless pipe production

PQF rolling mill for hot-rolled seamless pipe

“PQF”is short for “premium quality finishing”.

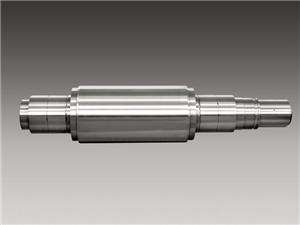

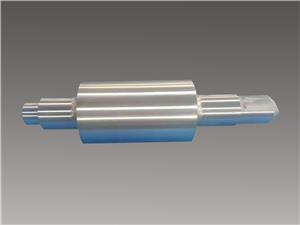

PQF continuous rolling mill is the very important part of the hot -rolled seamless pipe line,adopting with 3 rolls mandrels construction.With the deformation,the re-bar or billet can reach the aim for reducing in diameter and thickness meanwhile the raw material inner metallurgical constriction appears to line extension.To guarantee the good seamless pipe surface quality,the PQF rolling mill still uses mandrel to limit rolling but not floating mandrel.PQF rolling mill is between piercing mill and reducing-sizing rolling mill thus it has the very important transforming belt function.

In the middle of 1990s,the Innse company which longs to Italy is the first company who points out the ideal of pipe forming with 3 limit mandrels and name it as PQF(premium quality finishing).

What is the mainly advantage of PQF?

1. With 3 rolls rolling,the linear velocity difference at each point of the three-roll pass is small, the metal flows less laterally thus the deformation is more uniform.The surface quality of the steel pipe is improved meanwhile the wall thickness accuracy is improved:

2. Three-roll closed pass rolling makes the metal in a higher compressive stress state, reducing the occurrence of defects,improving the ability to roll thin thickness pipe, high-grade steel pipes and difficult-to-deform steel pipes.

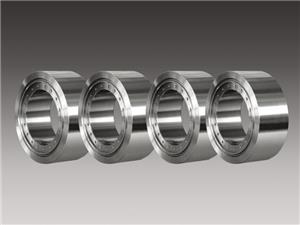

3. With 3 rolls rolling,it makes the unit rolling pressure distribution uniform.the pressure peak is low which improves the life of the rolls and mandrels and also creates conditions for controlled rolling;

4.In addition, due to the uniform deformation of the three-roll rolling, the generation of fins at the tail end of the waste pipe is reduced and the metal yield also rolling smoothness is improved.

5. The roll gap is adjustable: each roll has a separate hydraulic pressing device. The frame spacing is shortened,which can reduce the length of the mandrel and the construction cost.