Nine Dangerous Links in Steelmaking Plants and Preventive Measures

Nine Dangerous Links in Steelmaking Plants and Preventive Measures

Part 1: Adding molten iron

Greater risk factors:

Hot metal mixing refers to improper or wrong operation of hoisting personnel.

Types of accidents prone to occur

Scorching.

Main preventive measures

(1) Command the crane to lift the molten iron at the specified safe station.

(2) The crane commander holding the certificate shall instruct the crane to hoist the molten iron from the molten iron waiting position to the converter platform according to the standard whistle, gesture or special walkie-talkie.

(3) Do not hang the small hook that tilts the hot metal ladle before adding the hot metal.

(4) Before adding molten iron, close the explosion-proof door in front of the operating room window.

(5) Command all other personnel to evacuate the converter platform site; no one should pass in front of the furnace when the molten iron is being mixed.

(6) When mixing molten iron, the molten iron can not be pressed against the furnace mouth.

Part 2: Adding scrap

Greater risk factors:

There is water, damp waste, and closed containers in the scrap steel into the furnace.

Types of accidents prone to occur

Other explosions.

Main preventive measures

(1) Check that the scrap steel is free of water and moisture before lifting, otherwise, drying measures will be taken or stop using it.

(2) Before adding scrap steel, check that the explosion-proof door in front of the operation room is closed.

Part 3:converter smelting

Greater risk factors

Breakout, there is water on the ground in the area.

Types of accidents prone to occur

Other explosions.

Main preventive measures

(1) Before smelting,confirm that there is no water on the ground in the area.

(2) Regularly check the wall thickness of the furnace lining.

(3) Repair the furnace in time according to the furnace repair plan.

Part 4: gas recovery

Greater risk factors

Gas leaks during smelting.

Types of accidents prone to occur

Poisoning and suffocation.

Main preventive measures

(1) Oxygen lance holes and feeding ports on the flue should be provided with reliable nitrogen seals; the converter furnace should be equipped with gas detection and alarm devices across all platforms above the furnace mouth; personnel should not stay for a long time on the above-mentioned platforms .

(2) When the converter gas is recovered, the fan room is a Class B production plant and a second-level hazardous location. Its design should adopt fire and explosion-proof measures, and be equipped with fire-fighting equipment, fire alarm signals, communication and ventilation facilities.

(3) Gas recovery should be equipped with continuous carbon monoxide and oxygen content measurement and automatic control system; the oxygen content of recovered gas should not exceed 2%; automatic switching valve should be used for gas recovery and release, and the chimney should be used when the gas cannot be recovered and discharged to the atmosphere. An ignition device should be installed on the upper part.

(4) The converter gas recovery system shall be reasonably equipped with facilities for venting, venting, and purging.

Part 5: electric furnace smelting

Greater risk factors

The cooling water system of the electric furnace leaked into the furnace.

Types of accidents prone to occur

Other explosions.

Main preventive measures

(1) The cooling water flow distribution of each cooling part meets the requirements, and the inlet water temperature and pressure are normal. Observe the difference of the cooling water inlet and outlet flow at any time.

(2) Do not switch the cooling water pump station during work.

(3) Carefully observe the water-cooled block during smelting and after tapping. If water leakage is found, stop smelting immediately, press to stop, and do not shake the furnace.

Greater risk factors

Improper operation leaks steel, and there is water on the ground in the area.

Types of accidents prone to occur

Other explosions.

Main preventive measures

(1) Before smelting, check that there is no water on the ground in the area.

(2) Regularly check the wall thickness of the furnace lining, the condition of the refractory materials on both sides of the oxygen lance and the furnace door.

(3) Repair the furnace in time according to the furnace repair plan.

Part 6: temperature measurement and sampling

Greater risk factors

Manual temperature measurement and sampling in front of the furnace, the furnace turning speed is too fast, the furnace turning operation is out of control, and the steel is poured out.

Types of accidents prone to occur

Other explosions, scorching.

Main preventive measures

(1) Manual temperature measurement and sampling to observe the pressure in the furnace to slowly pour the furnace.

(2) Manual temperature measurement and sampling stand on the side of the fire door, and wear protective clothing.

(3) Check before smelting that there is no water on the ground in the area.

Part 7: tapping

Greater risk factors

The molten steel tanker does not pour steel in the correct position, and there is water on the ground.

Types of accidents prone to occur

Other explosions.

Main preventive measures

(1) Check and confirm the tapping point of the molten steel tanker.

(2) Slowly shake the furnace.

Part 8:converter smelting

Greater risk factors

The slag tank is not in place, there is water or damp waste in the spilled slag tank.

Types of accidents prone to occur

Other explosions.

Main preventive measures

(1) Check that the slag tanker moves to the slag discharge position of the converter, and the alignment is accurate.

(2) Check that there is no water and moisture-free waste in the slag tank.

(3) Check and confirm that there is no water and moisture in the slag channel.

Part 9: slag splashing to protect the furnace

Greater risk factors

Nitrogen leaks.

Types of accidents prone to occur

Poisoning and suffocation.

Main preventive measures

(1) Check the valve position and joints of the nitrogen system for no leakage.

(2) Check that there are ventilation facilities in the nitrogen valve room and there is no leakage.

(3) Before entering the nitrogen and argon valve chambers for inspection, ventilate and check with an oxygen detector before entering.

It is necessary for take care of each details in steel making company.And wish every steel company with safety production!

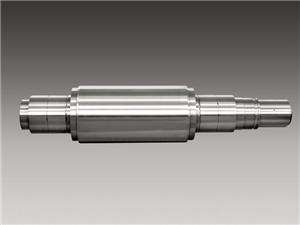

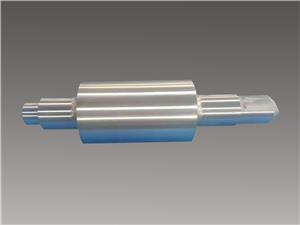

We make different rolls for hot strip steel,cold strip steel,sections,wire and rebar also rolls for seamless pipe.If any need,it will be highly appreciated!