Tungsten Carbide Rolls

- SDMT

- HEBEI

- within 75 days after advanced payment

- 800 tons/month

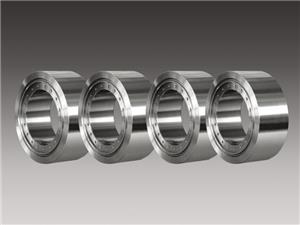

Tungsten carbide rolls

● wide adaptability

● high rolling accident resistance

● high wear resistance

● lower roll consumption

● according to the customer's rolling condition,personalized roll material design is carried out to reduce the user's roll consumption

Tungsten Carbide Rolls

Usage:The cemented tungsten carbide roll is mainly used on the finishing mill for re-bar,deformed steel bar and common wire.In this way,we can greatly reduce the frequency of changing roll,thus to reduce the labor intensity and improve the work efficiency.The surface quality is improved to a maximum degree which leads to a remarkable economic benefit.

Tungsten carbide roll specification

Outside diameter(mm) | Roll width(mm) | Rolling size(mm) |

285-480 | 50-140 | 5-28 |

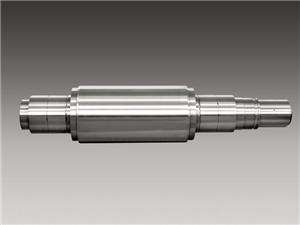

Rolling Technology for hot-rolled bar and deformed steel bar

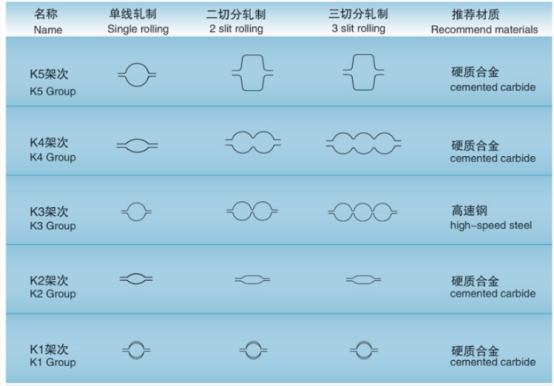

According to the production line and rolling technology of the customers,our products are designed to match to one-stand rolling,two slitting rolling and three-slitting rolling.The tungsten carbide roll includes K1 finished roll,K2 preforming roll,K4 pre-slitting roll&K5 slitting roll.The rolling products include wire,re-bar,deformed steel bar and the others.

We can effectively reduce the frequency of changing rolls and increase the yield after using cemented carbide composite roll.The rolling products possess the features of good surface quality,small deformation,negative tolerance and high production.